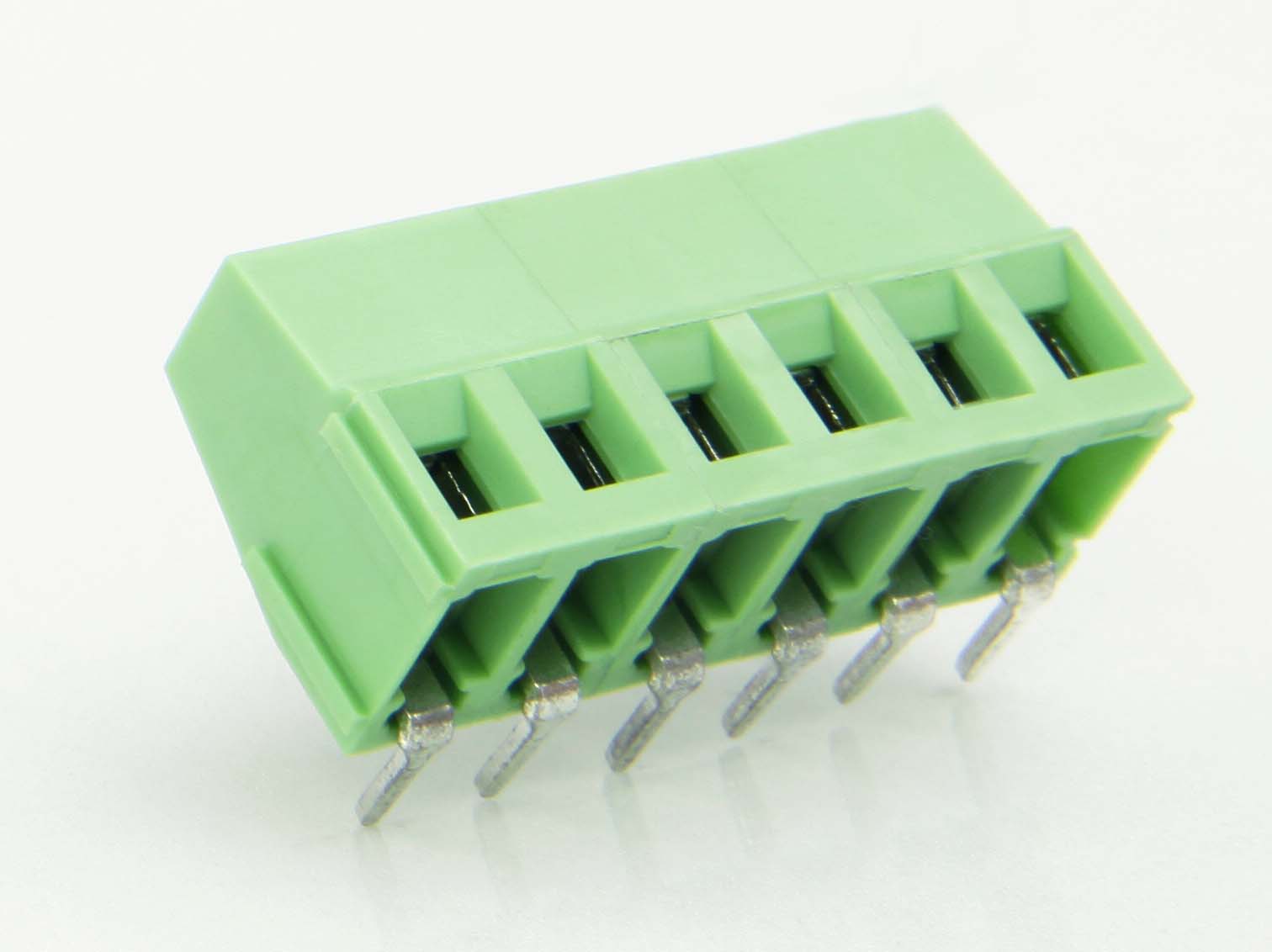

Introduction and material introduction of wire connectors

Introduction and material introduction of wire connectors

Wire connectors are actually wire connectors. We have seen a lot of wire accidents, some of which are caused by the overloaded use of the wires, and the other part is caused by the loosening of the wire connectors. Therefore, although the wire connector is small, it plays an extremely important role in circuit engineering.We have seen a lot of wire accidents, some of which are caused by the overload of the wire, and the other part is caused by the loose wire connector. The connector in the wire box is not up to standard. When the wire is not loaded, there is nothing wrong with it. As long as the switch is pushed on, it will trip, and there will be a few fires in the wire junction box. There is a tripping sound again. This phenomenon is all due to the improper wire connector and poor contact when the voltage is under load.

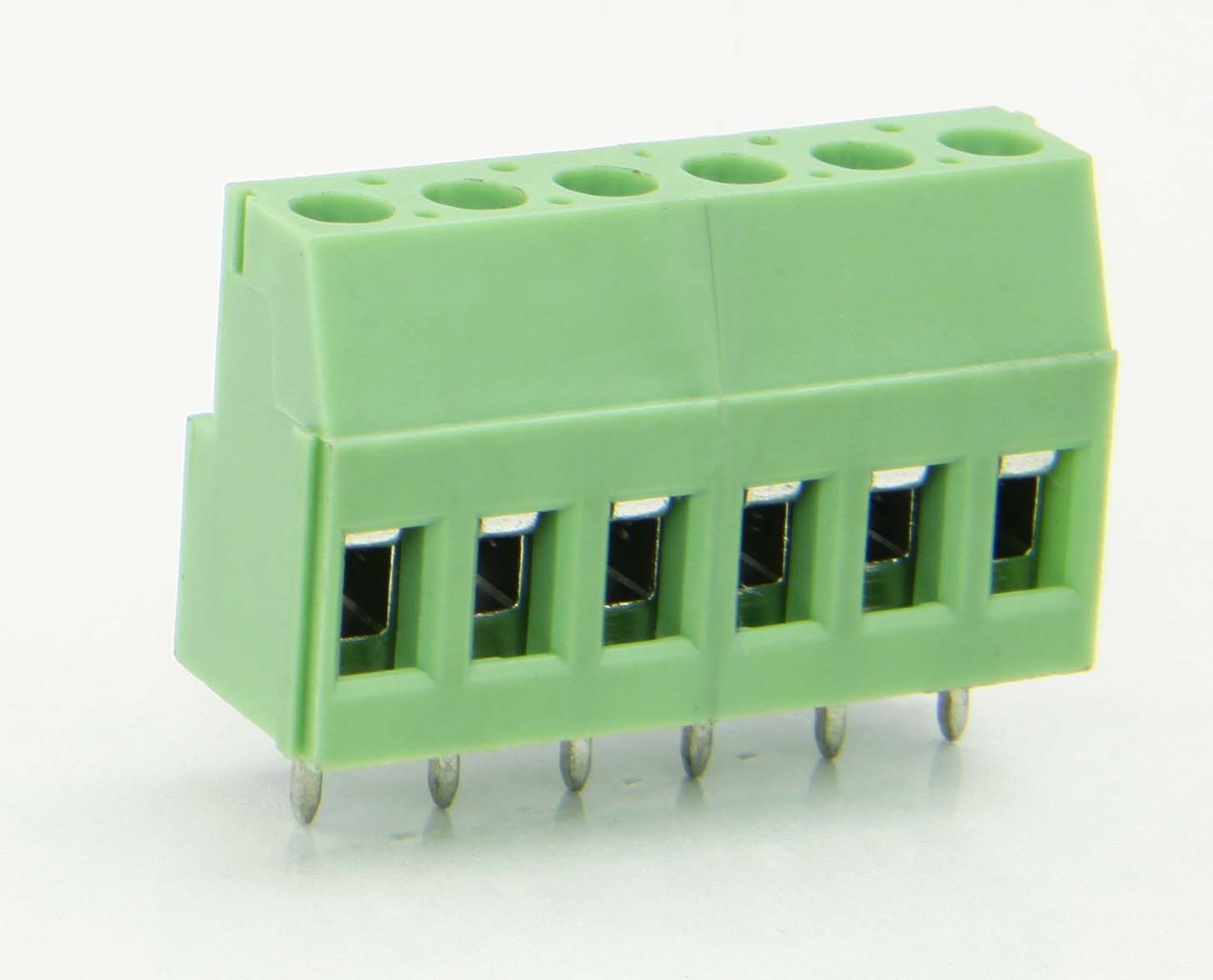

1. Insulation material (housing): Nylon 66 (resistance to leakage current breakdown, elasticity, rigidity, corrosion resistance, environmental protection without halogen and formaldehyde. Temperature -35℃-105℃).

2. Pressure reed material: steel (cold stamping (material processing by the die installed on the press) processing, high precision, no burrs, repeated use can maintain elasticity, strong tensile and corrosion resistance, and increase the resistance of wire insertion and extraction Wear capacity).

3. Contact material: thick electrolytic copper + tin plating (excellent electrical conductivity, thermal conductivity, ductility, corrosion resistance, prevent contact heating).

4. Contact point plating: tin plating (anti-corrosion, not easy to oxidize, good air tightness).

If you are interested in Wire Connectors,You can browse related products and initiate consultations on our website