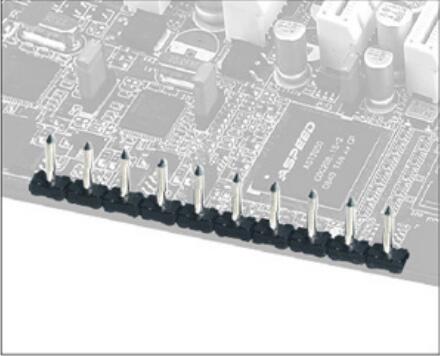

Introduction of Multi Pin Connector

Introduction Of Multi Pin Connector

The sealed multi-pin connector provides a high vacuum or ultra-high vacuum internal signal through a linear connection with an external instrument, and voltage or current is introduced or drawn. MPF can provide single-ended and double-ended connections.MPF multi-pin connectors are manufactured using different U.S. military standards according to the use, installation method and number of pins. MPF's multi-pin connectors are Sub-C, Sub-D, MS ring, with base, ring multi-pin, high voltage, high current.

Application of MPF multi-pin connector

Semiconductor processing equipment

Analysis and measurement equipment

Pressure Sensor

Power generation equipment (measurement and control technology)

Particle accelerator

furnace

Energy Research

The MPF connector is composed of sealed and welded ceramic metal parts or glass ceramic parts. The design of glass ceramic parts can reduce the overall stress to a minimum, thereby improving the overall operational characteristics.

All parts are made of high-purity materials suitable for use in a vacuum environment. The insulator is made of high-strength, low-loss ceramics. These ceramics use a sintering process to make them have the characteristics of metallization. The metals include stainless steel, nickel-iron alloys, copper-nickel alloys, and molybdenum steel alloys. Assembled parts can be welded using copper, copper-gold or silver-copper alloys.

The standard instrument plug is round design

If the vacuum plug needs to be used at a higher operating temperature, Ceramtec can use Teflon® or ceramic components instead of resin components

MPF uses advanced technology and methods to control key steps, including 100% helium leak detection test and X-ray measurement to control the metallization process.

If you are interested in Multi Pin Connector,You can browse related products and initiate consultations on our website.